What type of welding is used in construction

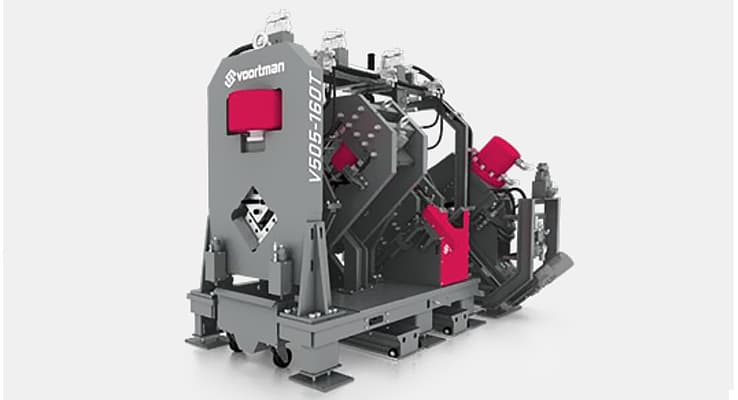

It is now possible to make custom beams at a fraction of the cost. Beam Layout Welding will increase your production on both tapered and straight beams. It automatically joins the beam's flanges, allowing for maximum penetration of up to 1/2" web and 1 1/2" flange. The PHI System produces a fillet joint between the web, flange. Welds are uniform in quality and conform to construction codes.